Hits: 909 img

Scientists at Zhejiang University have developed an ultra-light material, called an "all-carbon aerogel," with a solid density of just 0.16 milligrams per cubic centimeter, one-sixth the density of air and the world's lightest material to date.

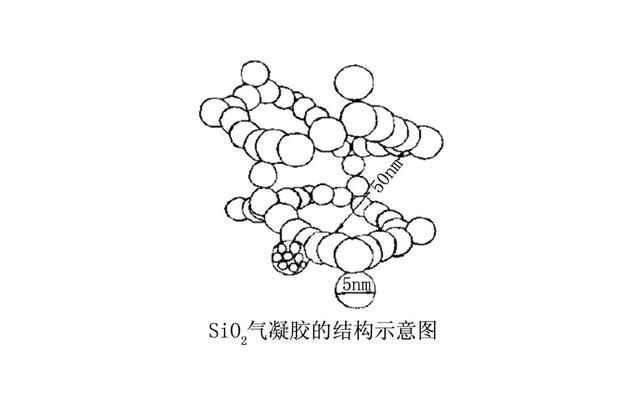

"Aerogel" is the product of semi-solid gel after drying and removing solvent, the appearance is solid, and the interior contains many pores and is filled with air, so the density is very small. The research team of Professor Gao Gao of the Department of Polymer Science and Engineering of Zhejiang University freeze-dried an aqueous solution containing two nanomaterials, graphene and carbon nanotubes, at a low temperature to remove water and retain the skeleton, and successfully set a new record for "lightest material". The previous "world record holder" was a material called "graphite aerogel" made by German scientists in late 2012 with a density of 0.18 milligrams per cubic centimeter.

"The structure of the all-carbon aerogel is similar to that of the carbon sponge. Even if you put a mug-sized aerogel on the setaria grass, the delicate beard will not be bent."

Although it looks "fragile", the "all-carbon aerogel" is excellent in terms of structural toughness, it can be compressed thousands of times to 20% of its original volume after rapid recovery. In addition, "all-carbon aerogel" is also one of the most oil absorbing materials. Existing oil absorption products generally can only absorb about 10 times their own mass of organic solvents, and the absorption amount of "all-carbon aerogel" can be up to 900 times its own mass.

The results were published online February 18 in the journal Advanced Materials and illustrated in the "Research Highlights" section of Nature. "All-carbon aerogel is expected to play an important role in environmental pollution control such as offshore oil spills, water purification and even air purification." Traditional aerogel production methods are often unable to mass production, but the research group's new "low temperature freeze-drying method" makes the production process of aerogel more convenient, but also makes it possible to large-scale manufacturing and application of this ultra-light material.

It is understood that the laboratory is currently conducting further applied research on the adsorption properties of this material, in addition to pollution control, "all carbon aerogel" will also become an ideal energy storage and insulation, catalytic carrier and sound absorption material.