Hits: 848 img

Aerogel insulation felt has excellent thermal insulation, high temperature and fire resistance, and is widely used in industrial and construction fields.

First, aerogel insulation felt pipeline insulation construction steps

1, before installing pipeline insulation materials, ensure that the steam pipeline is anti-corrosion construction, and then clean the pipeline.

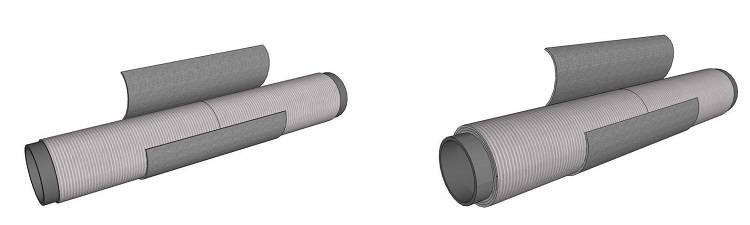

2. The position of the horizontal axial overlap joint of the insulation material shall not be arranged within the range of 45 ° C of the vertical center line of the pipeline, as shown in the following figure.

3. When covering the aerogel insulation felt, cut the aerogel insulation felt to the length required for laying a circle. The cutting length can be determined by directly wrapping the strip aerogel insulation felt or measuring the circumference of the pipeline with a tape measure. Lay the cut aerogel insulation felt close to the pipe with a certain force, and align the edges of the two ends of the material. The starting end is fixed with glass fiber tape or galvanized iron wire, and then the other end of the aerogel insulation felt is fixed on the pipe in the same way, and then every 200~300mm bundled. The parts with vibration should be strengthened bundling, such as the use of galvanized iron wire as bundling material, the force should be moderate, should not destroy the thermal insulation layer, galvanized iron wire can not be embedded in the insulation felt, galvanized iron wire joints should be flattened.

4. The splicing of each section of aerogel insulation felt should be tight, all the circumferential and longitudinal joints should be jointed, the seam width should not be greater than 2mm, and the direction of the axial lap joint of the same layer should be consistent. Joints with a width greater than 2m should be filled with aerogel insulation, and if necessary, aluminum foil tape can be used to seal the joints.

5, multi-layer aerogel insulation felt construction, should be constructed layer by layer, layer by layer binding, each layer of aerogel insulation felt should be tightly fitted, insulation layer construction of the same layer should be staggered, the upper and lower seams should be pressed, the pressing joint distance between the two adjacent layers shall not be less than 200mn.

6. When single-layer aerogel insulation felt insulation structure is used, after the completion of the construction of the aerogel insulation felt, a layer of aluminum foil thermal reflection film should be covered on the outside of the aerogel insulation felt (can also be directly used with aluminum foil glass fiber cloth aerogel insulation felt). When double or multi-layer aerogel insulation felt insulation structure is used, a layer of aluminum foil thermal reflection film should be covered on the outside of the secondary outer insulation felt.

7. After the construction of the outermost aerogels insulation felt is completed, the glass fiber cloth should be wrapped around the aerogels insulation felt. During the wrapping, the glass fiber cloth should be pulled tightly with certain strength to tighten the lap joint. The size of the glass fiber cloth is not less than 50mm, and it is recommended to be 1/2 of the width. The width of the glass fiber cloth should be 200mm~300mm, such as the aergel insulation felt with aluminum foil glass fiber cloth used in the outermost layer, there is no need to wrap the glass fiber cloth.

For both ends of the flange, use a 50mm wide glass cotton pad to ensure the same height of the flange rings, and use a 50mm wide aerogel thermal insulation felt pad to ensure the same height of the two flanges connecting the valve and pipeline. Then, insulation can be performed.

For special parts such as curves, tees and reducing pipes, aerogel insulation felt can be cut or spliced into a corresponding shape for laying and fixing, which is similar to the above insulation construction method.

Second. Quality acceptance

1. Acceptance quantity

The inspection quantity of insulation layer and protective layer shall comply with the following provisions:

(1) When the length of the pipeline is every 10m or less, 2 spots should be checked, and no less than 3 spots should be checked at each spot

(2) When the length of the same pipeline exceeds 300m, the spacing of the sampling inspection can be appropriately increased

(3) The inspection number of elbows, valves and flanges is 4 for every 10 spot checks

(4) When there is 1 unqualified in the quality inspection, it should be doubled near the unqualified point to review, and when there is still 1 unqualified, it is identified as unqualified.

2, quality acceptance

Proceed as specified in 3.2 of GB/T 50185-2019.